Valmetal

Valmetal Nordic 215 Silo Unloaders

Three 5/16" galvanized aircraft type cables support the unloader from 3 widely spaced points which result in a level cut from top to bottom.

The drive ring's large diameter along with wall to wall suspension arms guarantee the perfect equilibrium of the machine without counter weight that has to be adjusted every now and then to match silage conditions. Made of 3/16" thick steel, the 3 ring segments feature a big 9' diameter on the 12' to 20' models. They are reversible giving them twice the durability. Double 48" long splice plates provide rigidity to the whole assembly. On the 24' models, ring segments are beefed-up and make a large 11' diameter ring for a stable and well-balanced machine.

The massive 10" heavy-duty auger made of 1/4" thick flighting welded on a 4" O.D. tube for rigidity. It is double flighted at the chipper wheel and to allow the machine to run smoothly in frozen and hard-packed silage. Sharp hardened knives can be installed on auger to chop up to toughest material. Coupled to the gearbox by a 3-bolt flange coupling, the auger assembly is easy to remove.

Valmetal 2000 Ring Drive Distributor/Unloaders

- Collector ring totally enclosed

- Electrical power is transferred from stationary to rotating part of the machine by extra-large brushes and thick copper alloy rings

- Large taper roller bearings inside the housing support the machine

- Heavy triangular suspension arms to avoid bridging

- Spring-loaded guide wheels to accomodate uneven silo walls

- Weight is evenly distributed on two large carriage wheels

- Six replaceable hardened steel blades keep the silo walls free of frozen materials

- The auger support features a solid oilite ball bearing, self lubricated, it resists moisture and contaminants

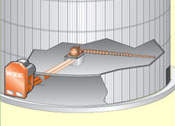

Valmetal Grain-O-Matic - Borrom Grain Unloader

- The tapered sweep auger drops feed into the "positive flow" hopper at the center, where spinning paddles cycle the material into the exit auger

- Grain does not just feed down through a center "cheminey" when you feed out as with some high-moisture grain unloader

- Grain is less likely to harden near the structure floor

- 13 H.P. electric motor

- Belt drive 50 and 140 rpm

- Quick action motor mount release

- 10 gauge steel hopper

- Tapered sweep auger shaft and flighting, 3" increasing to 5"

- Quick action low clearance discharge hatch

- Drive mechanism ratchet type overload protection